Tiles KPIs

In this page you will find the definitions and calculations for the different Tile+ KPIs according to the Worximity environment.

Performance

Quantity & Quality

* Note these KPIs require an additional hardware configuration and some may apply extra fees.

Definition

It is the percentage that measures how often your production line or equipment operates as scheduled compared to the accurate total production time. It indicates whether your operations are on track or experiencing downtime.

Target Availability displayed is predefined per production unit /line.

Calculation

Availability (%) = (Uptime/ Scheduling Working time)100

Ex.: (Total Uptime 6 hrs / 8 Scheduled hrs )100 = 75% Availability

Uptime = Actual production time after planned and unplanned downtimes.

OOE's Availability = (Actual Production Time / Potential Production Time)100

Definition

Total Downtime duration, categorized as planned or unplanned, within a selected timeframe( Production day/ Shift/ Hour).

Note:

Unplanned and planned downtimes are configured in the Downtime Reasons section of the admin menu.

Planned downtime is excluded from the OEE calculation.

Most of planned downtimes should have a target duration to improve tracking of extra time in those tasks.

Definition

Indicates the number of downtimes in a selected time interval, that require justification.

By clicking this tile the Justification Panel will open and the user will be able to add a Downtime Justification cause.

Note:

The downtime delay and justification delay at the Production Unit admin menu, will influence the quantity of downtimes your operators need to justify.

Rule of thumb: Ideal quantity is less than 15 by shift.

Definition

Performance is the ratio of the actual quantity produced for the selected product against the target quantity.

Calculation

Performance (%)= (Actual rate / Target rate)100

Ex.: A product is actually running at a 850 u/h rate but it's target is 1000u/h .

Performance will be 85%

Definition

This is a measure of the number of product units produced per unit of time, when the line is active.

The rate target is predefined by product and per Production Unit.

Rate tiles can now be selected in various dimensional units, including weight, length, and volume.

To display data in any unit, a valid conversion chain must exist.

For weight-based cadences, Tile+ uses the theoretical weight for lines without checkweighers or for sampling sessions weight. For lines with checkweighers it will use actual recorded weight.

Calculation

Rate (Units/h*) = Quantity / Uptime

* Divide by 60 to convert to minutes, and by 3600 to convert to seconds.

Definition

Represents the average speed of a product (SKU) over the last 5 minutes.

Takes into count Uptime & Downtime in that 5 min span.

Note:

Speed displays LIVE values only at the Current Time, meaning that if you navigate in the past to select previous date/time slots, the KPI won't display values.

To display the speed in various dimensional units, including weight, length, and volume it is required to enter the appropriate unit conversions.

Calculation

Instant Speed (units/hr or min or sec) = Net quantity / (uptime + downtime unjustified + downtime unplanned)

What is the difference between Speed and Rate (units/min)?

-

Speed is the number of units produced over a given period of time, whether or not the line was running during that entire period. It represents OOE in terms of units produced per time period.

-

Rate is the number of units produced over a given period of time, but only while the line is running.

Example:

A production unit may run at a Rate of 10,000 units/hour, but if it is active for only 30 minutes due to downtime, it would actually produce only 5,000 units/hour. The Rate remains 10,000 units/hour, while the Speed reflects the effective 5,000 units/hour.

Quantity & Quality

Quality is one of the three key components of the OEE, focusing on reducing defects and ensuring that the produced items meet the required specifications and standards.

Definition

Net Quantity - calculated once the Manual Reject Form has been used to record Rejected units, for a Specific SKU, using the same unit type and scale (this is configured beforehand in Admin/ Product/ ...

Rejects

The Sum of the Rejected Qty for each SKU.

Entered manually using the Manual Reject form.

Note:

To be able to select this tile, you must contact your account manager to activate the Rejections module.

Calculation

Net Quantity - unit = Production Run Quantity - Reject Quantity.

Definition

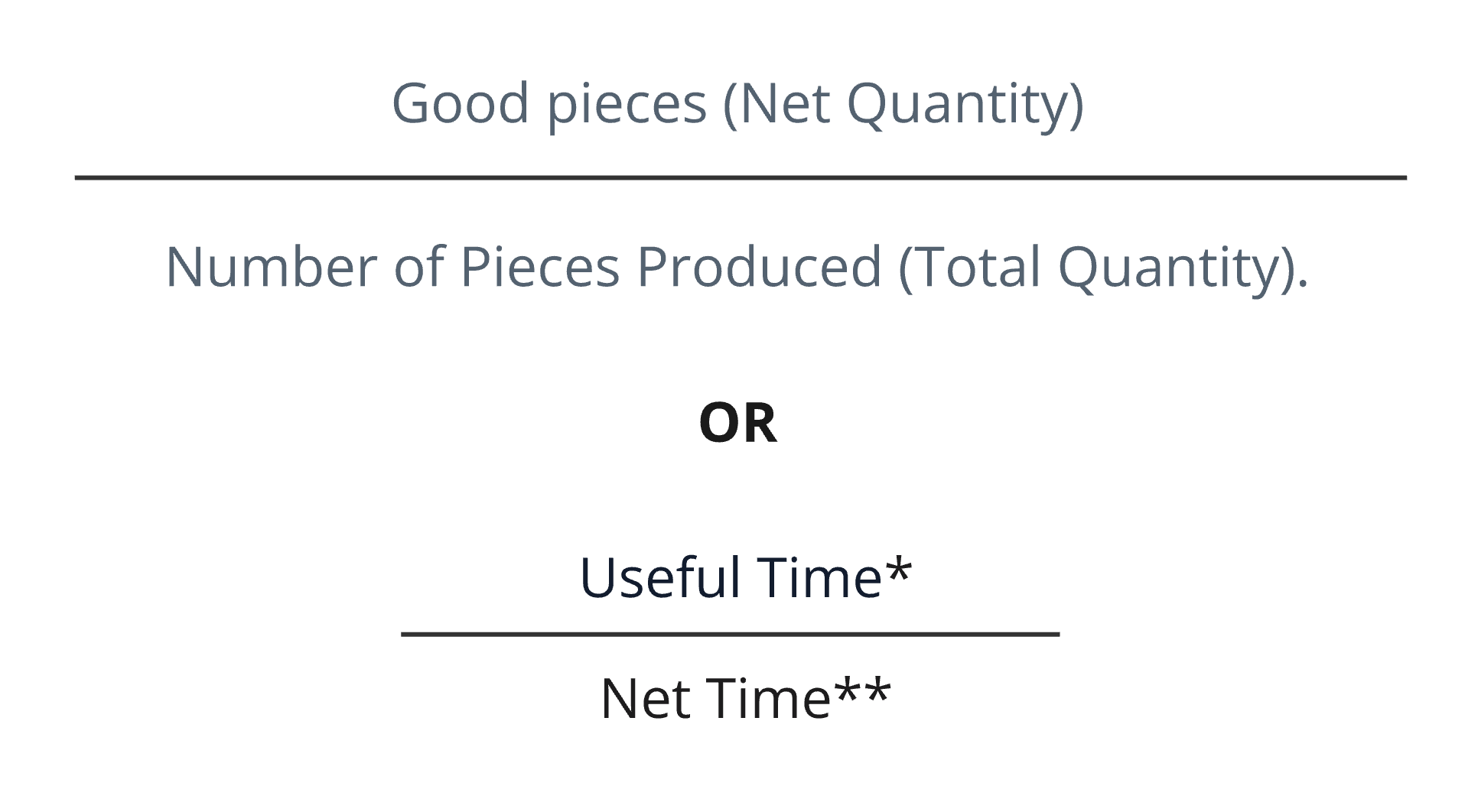

Ratio between the number of good pieces (Net Quantity) and the number of pieces produced (Total Quantity).

Since the units produced can vary from one piece of equipment to another in a whole production line—for example, some machines count in cans while others count in boxes—we use time as the common reference.

All the components of OEE can be converted into time, which makes it possible to calculate Quality as follows:

Useful Time / Net Time

-

Useful Time: part of the Net Time corresponding to the measurable time obtained by multiplying the number of good and bad pieces, based on the reference cycle time.

-

Net Time: part of the operating time during which the production equipment would have produced good and bad pieces, based on the reference cycle time.

Definitions according to AFNOR standards

Note:

The target quality displayed is predefined by production unit/line.

By default, the quality factor is set to 100% if the reject module is not configured.

Worximity supports different use cases for counting rejects.

Giveaway

Definition

Represents the current SKU’s ratio for the Average Measured Weight vs the Target SKU weight (as configured in the Admin/Products/.. section).

If the giveaway value is under the Target (negative or positive) display green, under 1% of difference yellow, above 1% difference show red.

Notes:

Average Measured weight input can be from:

1- the Sampling Dashboard, via table top scale input.

2- Connected Checkweigher/ Blackbox, feeding SKU weight data into Tile+.

Calculation

Giveaway % for a SKU = 100% * (Average Weight - Target Weight) / Target Weight

Definition

Represents the current SKU’s Sum of measured weights above the Target Value – which is configured in the Admin/Products/... section.

It doesn't have a Target because the Tile+ business rules do not yet calcualte Cumulated Quantity of Giveaway. This is only accounted for in the %Giveaway KPI for now.

Example of the Calculation

Ex.: 100 samples were taken of the 5,000 units produced.

The Giveaway % of those 100 samples = 2%

according to the Product Target weight which is 100g. This represents 2g per unit.

Therefore, the Giveaway of the 5000 units produced is:

2g * 5,000 units = 10,000 g (10 Kg)

Definition

Average weight of all your the produced units if you have a check weigher, or if you have a Sampling- Giveaway module it would be the average of all your samplings during an specific period.

Calculation

Average Weight* (kg*) = Sum(weights measured) / Number of weighed instances

*supported: unit of weight, volume or length

OEE

Definition

Overall Equipment Effectiveness is the product of availability, performance, and quality for a given production line and time frame.

The OEE score indicates your current status, while its different factors - Availability, Performance, and Quality - help you to identify the loss areas and where to focus the improvement efforts.

Learn More about OEE Losses here

Overall Operations Effectiveness (OOE)

Navigating the various terms and nomenclature in the industry for denoting OOE (Overall Operating Efficiency) can be confusing. Some might refer to it as General Efficiency, while others may argue it's OEE2. The key takeaway is understanding the type of availability factored into the calculations. At Worximity, we define OOE by considering both Planned and Unplanned downtime, meaning the Actual Production time Vs the Scheduled time.

Definition

Overall Operations Effectiveness (OOE) measures line productivity based on its active usage time.

A 100% OOE indicates continuous operation at maximum speed and production of only high-quality goods. Any downtime (planned or unplanned), speed reduction, or production of defects reduces the OOE percentage.

Learn More about OOE and OEE Losses here

Calculation

OOE (%) = Availability (%) (Availability = Actual Production Time / Potential Production Time) x Performance (%) x Quality* (%)

Ex.: 50% Availability x 90% Performance x 96% Quality =43.2% OOE

Production Run Completion

Definition

Production completion is the ratio of the units produced against the target quantity of the current product at the specified time.

Note:

Planned Quantity can be added when selecting a New Product / Production run or using the Product Change API.

Calculation

%Completion of current SKU = Sum(unit count) / Planned Qty count*

*Planned Quantity Count: can be added while Selecting a SKU in Tile+. If it is not added, %Completion is represented as a null "-" value.

Definition

Time to Completion is the duration (hh: mm) required to produce the Planned Quantity of a Production Run, with the time-varying based on the Production Run Speed.

Any downtime or slowness will affect the time.

Note:

This tile is designed to work only when a Planned Quantity is entered for a Production Run.

It will only display values for the current production run and cannot show values from the past. If there is a change in production run or you navigate to past time frames, the tile will display a null "-" value.

Calculation

Time to Completion of current Production Run =(planned quantity - produced quantity) / Production Speed

Definition

The number of times the equipment went on, which can represent the number of batches produced.

Note: Even when this tile can be selected and display data, it won't be accurate since it requires additional hardware configuration.

Calculation

Cycle Count= Sum(Cycle Counts) for the selected time frame*

*Production Day / Shift / Hour Production Run

Definition

It calculates the time the equipment is in function versus the average time of all uptime sequences recorded.

Note: Even when this tile can be selected and display data, it won't be accurate since it requires additional hardware configuration

Calculation

Current Cycle Time = Delta Time in between Downtimes.

Average Cycle Time = Sum (Cycle Times) /Cycle Counts for time frame*

*Production Day / Shift / Hour Production Run

Tiles Status

Users in Tile+ can track different KPIs, 4 at a time, in the Line Dashboard.

Depending on the selected KPI the Tiles will display different relevant information.

Status: The colour of the circle changes to yellow when the measurements decreases from 5% of the target, and it turns red when the measurements are off target of 10%.

Only the KPIs with a Target display a Status